Semi-Automatic/ Automatic Block Production Line QT12-15

Introduction

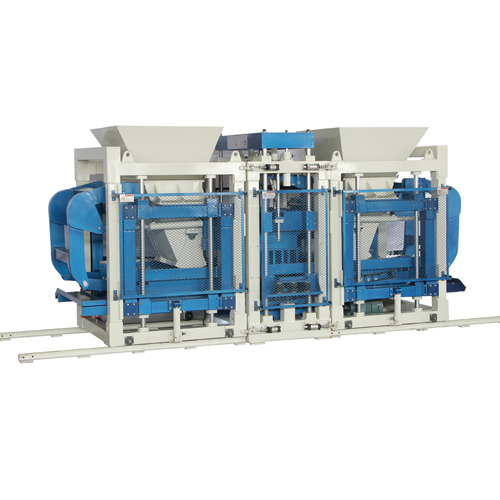

Automatic block production line consists of two systems: batching and mixing system, block forming and stack system.

All equipments needed for the line are as follows: PL1600 batching machine, JS1000 compulsive mixer, QT12-15 block making machine, and stack machine.

Drawing of the Automatic Block Production Line

Batching machine includes batching, weighting and electron control unit; batching part includes the loading hoppers, store hoppers and the mainframe.

1. PL1600 Batching Machine

|

1

|

Volume

of Scale hopper

|

1600L

|

|

2

|

Volume

of Store hopper

|

3000L

x 4

|

|

3

|

Power

of motor (kw)

|

17.5

|

|

4

|

Productivity

(m3/h)

|

75

|

|

5

|

Work

Cyc (S)

|

55

|

|

6

|

Measurement

accuracy

|

<2%

|

|

7

|

Specification

( Lx Wx H) (mm)

|

12840x2300x2500

|

|

8

|

Weight

(kg)

|

4800

|

2. JS1000 Compulsive Mixer

It can work by itself and also can work with the batching machine to build up a mixing station

|

1

|

Volume

of Input Hopper

|

1600L

|

|

2

|

Volume

of Output Hopper

|

1000L

|

|

3

|

Productivity

(m3/h)

|

>=50

|

|

4

|

Maximum

Grain Size of Material (mm)

|

80/60

|

|

5

|

Number

of Stirring Blades

|

2x8

|

|

Rev

of Stirring Blades (r/min)

|

30.5

|

|

6

|

Power

of Stirring Motor (kw)

|

37

|

|

7

|

Power

of Windlass Motor (kw)

|

11

|

|

8

|

Power

of water pump (kw)

|

3

|

|

9

|

The

upgrade speed of hopper (m/s)

|

0.36

|

|

10

|

Specification

( Lx Wx H) (mm)

|

5930x2250x4960

|

|

11

|

Weight

(kg)

|

7000

|

3. QT12-15 Block Making Machine

Our company is one of the leading manufacturers of QT 12-15 automatic concrete block making machines in China. With more than 20 years’ production experience, we can make use of various raw materials for production, such as crushed stone, sand, cement, dust, coal fly ash, cinder, slag, gangue, gravel, perlite and other industrial wastes. As the moulds are changeable, this block making machine is able to produce various kinds of hollow blocks, solid bricks, interlocking bricks, pavers, curbstones, and so on.

QT 12-15 automatic concrete block making machine is extensively used in building, road paving, square, garden, landscaping, city construction, and so forth.

Features of Block Making Machine

1. Double oil cylinder drives crank arm connecting rod system is used on feeding system. Material feeding can be quicker, more sooth and steady.

2. Motor reducing gear is used on rotation device in the feeding box.

3. Four terminal input vibrators are used on the vibration table. Special design for vibration table stand to make vibrating force equally distributed, and all products height keep accordant and forming faster.

4. VFDs motors are used to control the vibration tale amplitude and frequency to fit for different moulds and products.

5. Air suspensions are used on the mould box .Adjustable damping can reduce working noise and prolong the machine service life.

6. PLC intelligent control and man-machine interface system can do random signal analysis, fault diagnosis and parameter setting during the whole process and insure the machine keeps best working effect.

7. It adopts fully hydraulic variable frequency vibration to realize accurate and adjustable vibrating speed. This automatic concrete block making machine also overcomes the defect that the motor will be damaged after long-term work and meets different production requirements of raw materials.

Parameters

|

Model

|

Cycle Time (s)

|

Pallet Size (mm)

|

Power (kw)

|

Weight (Kg)

|

Specification (mm)

|

|

QT12-15

|

12—18

|

1400x900x30

|

62.5

|

15600

|

11200x2500x3100

|

Capacity

|

Type

|

specification (mm)

|

No./pallet

|

Block/hour

|

Block/8hours

|

Remark

|

|

Block

|

400×200×200

|

12

|

2880

|

23040

|

|

|

Hollow Block

|

240×115×90

|

30

|

7200

|

57600

|

|

|

Solid brick

|

240×115×53

|

60

|

14400

|

115200

|

|

|

Paver

|

200×100×60

|

48

|

11520

|

92160

|

|

4. Cement Scale

The cement scale hangs on the mixer. It buildup by hanging shelf, pull sensor, electron-steelyard and valve. It is used to scale the weight of the cement. Used for cement laden in bulk, if you use cement in bag, you can add cement by manual, no need for

5. Water scale

The water scale hangs on the mixer. It buildup by hanging shelf,

pull sensor, water tank and water pump. It is used to scale the water

6. Belt conveyor (transport mixed material to block making

machine)

7. Screw conveyor (Transport bulk cement from cement

silo to mixer)

|

8.Face feeding device (Optional, to make color paver)

|

|

|

9. Stacker

|

10.Mould

|

|

|

Related Products